How Reflow Soldering Contributes to Circuit Board Assembly

Reflow Soldering Contributes to Circuit Board Assembly

Reflow soldering is a key component of circuit board assembly, and one that contributes to high-quality, reliable solder connections. While reflow soldering does have some challenges, the right materials and careful handling can help overcome these issues.

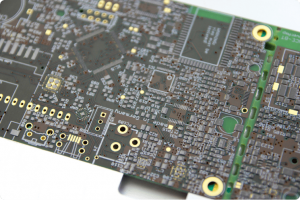

A printed circuit board (PCB) provides a base for mounting and interconnecting all the components that form the functional elements of an electronic device. Surface mount components, also known as SMDs, are the most common type of component used in PCBs. These SMDs are mounted on pads on the PCB, which are coated with solder paste. The solder paste acts as the interface between the components and the PCB, creating strong and reliable connections between them.

To begin the reflow soldering process, the SMDs are placed on the pad with the use of a pick and place machine, which uses cameras and robotic arms to accurately position the components. After the SMDs have been properly positioned, they are transferred to the solder reflow oven.

During the reflow soldering process, each component is exposed to carefully controlled temperatures that allow it to melt and solidify, forming an effective connection with the PCB. The SMDs must meet the minimum reflow temperature set by the manufacturer of the solder paste to ensure that it will effectively melt and flow when warmed above its melting point. Moreover, the temperature profiles must be designed to ensure gradual and controlled heating and cooling rates so that the entire surface of the PCB can be heated evenly without overheating the delicate components.

How Reflow Soldering Contributes to Circuit Board Assembly

Incorrect reflow oven setup or the use of an incompatible profile can result in a variety of defects. Some of these are characterized by uneven heating that can cause some parts to reach the reflow temperature before others, resulting in mechanical stresses and potential failure. Other defects include uneven wetting between the component and pad, tombstoning, and oxidization. Using a custom profile that aligns with the specific needs of the PCB and solder paste can reduce these problems.

Oxidization occurs when the surface of a metal component comes in contact with oxygen during the reflow soldering process. This can cause corrosion of the metal and affect its durability and environmental robustness. To avoid oxidation, it is essential to use low-reactivity fluxes in the reflow soldering process and to carefully control the temperature of the reflow oven.

Reflow soldering offers many benefits for circuit board assembler, including faster and more accurate assembly of complex electronics. However, the reflow process can be challenging because of the high temperatures and specialized equipment involved. To successfully use this process, it is important to understand the reflow soldering cycle, choose the right materials, and follow best practices for each step. By doing so, you can be assured of high-quality, robust solder joints in your final product. FS PCBA is an experienced circuit board assembly service that uses precise reflow soldering techniques to achieve high-quality electronic assemblies for customers. Contact us today to learn more about our services and how we can support your business.