How Do You Choose the Right Material For a Flexible PCB?

Choose the Right Material For a Flexible PCB

When it comes to making a PCB, the material choice has a significant impact on the final product’s functionality and manufacturability. The right material can also save you money and make the process of designing and assembling your PCB much more efficient. The wrong material can leave you with a circuit board that doesn’t meet your needs or one that is less durable. It’s important to choose the right materials for your project based on its environmental requirements, assembly timeline and manufacturing processes. If you’re unsure of how to select the best materials for your PCB, you can always reach out to your manufacturer for consultation.

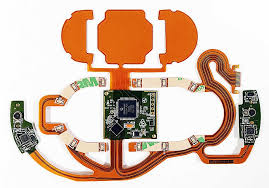

A flexible printed circuit board is a complex electronic device that is used in applications that require a high degree of flexibility, which is why the PCB must be made from a flexible material. It should be able to handle bending and vibration without losing its integrity or function. It is also important for the flex PCB to be able to operate in a variety of environments and temperatures.

The choice of a flexible PCB material is an important decision that will affect its performance and cost. The FR-4 laminates typically used in rigid PCBs are not appropriate for a flex circuit. A flexible pcb must be able to bend and flex with minimal deformation or failure, and a thinner material like FR-4 will not provide this level of flexibility.

Another key consideration is signal integrity. The ability of a flexible circuit to maintain the shape and waveform of electrical signals passing through the copper tracks is essential. This is particularly important for applications that will use the flex circuit in mobile devices or other demanding environments where the device may be subjected to vibrations and temperature extremes.

How Do You Choose the Right Material For a Flexible PCB?

A flex PCB should be able to withstand high levels of heat, which is why it is important that the underlying layer of the circuit board is a thermally-conductive material. This helps ensure that the board will be able to disperse excess heat during operation, and prevent the occurrence of a catastrophic failure caused by overheating.

There are a number of different materials that can be used for a flex circuit, but the best choice is usually a polyimide. This is a high-performance material that offers superior flexibility, dimensional stability and resistance to chemicals. It also has a high glass transition temperature, which is ideal for flex circuits that will be subjected to a range of environmental conditions.

In addition, a flex PCB must be free of halogens. This is essential for applications that will be used in the European Union, where it is mandatory to use halogen-free circuit boards. In addition to being safe for human use, halogen-free materials are safer for the environment and will reduce the risk of fire or explosion. In addition, they are also easier to recycle, which can help reduce waste.

Signal integrity is paramount in flexible PCB design to ensure reliable data transmission. Factors such as impedance matching, signal reflections, crosstalk, and skew must be carefully managed. Techniques like signal termination, controlled impedance routing, and simulation tools help optimize signal integrity on flexible PCBs.